- Home

- /

- Applications

- /

Mining

Mining

The use of geosynthetics in mining operations is growing annually, as mining companies focus on the technical and economic advantages of geosynthetics. These materials have enabled more efficient barriers, stronger access roads, space-saving and safety-enhancing retaining structures.

Geosynthetic solutions for the mining industry are engineered for long-term performance in all environments and with the chemical compatibility necessary to meet the economic and environmental goals of today’s mining operations.

Construction of Tailing Pond Scaling up of containment frequently requires not just lining systems but reinforcement and sealing systems for perimeter berms on tailings pond. Weaker, earthen-only berms are at risk of saturation, erosion, and failure. Furthermore, the increasing depth of tailings storage ponds requires stronger containment engineering design.

for onsite water management and processing fluid containment, geomembranes are an economical and efficient solution.

Geomembranes are not all that mining sites require. Nonwoven geotextiles provide long-term, robust protection of and frictional stability for geomembranes on difficult terrain and in tall ore stack scenarios. Additionally, composite lining solutions (geomembranes with geosynthetic clay liners, GCLs) provide dependable, efficient, long-term lining performance for improved heap leach economics and environmental performance if used in a mining operation.

Products Used

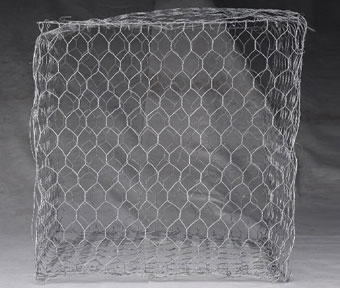

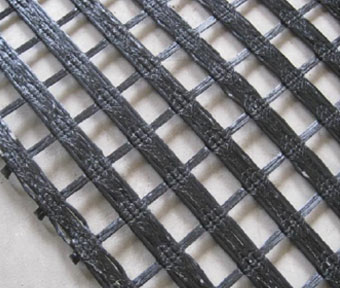

Many mines have dump and head walls, which can be more than 25m high. The combination of geogrid reinforcement and facing Gabion can be designed to withstand high vertical and horizontal loading from heavy vehicles as well as seismic activity.